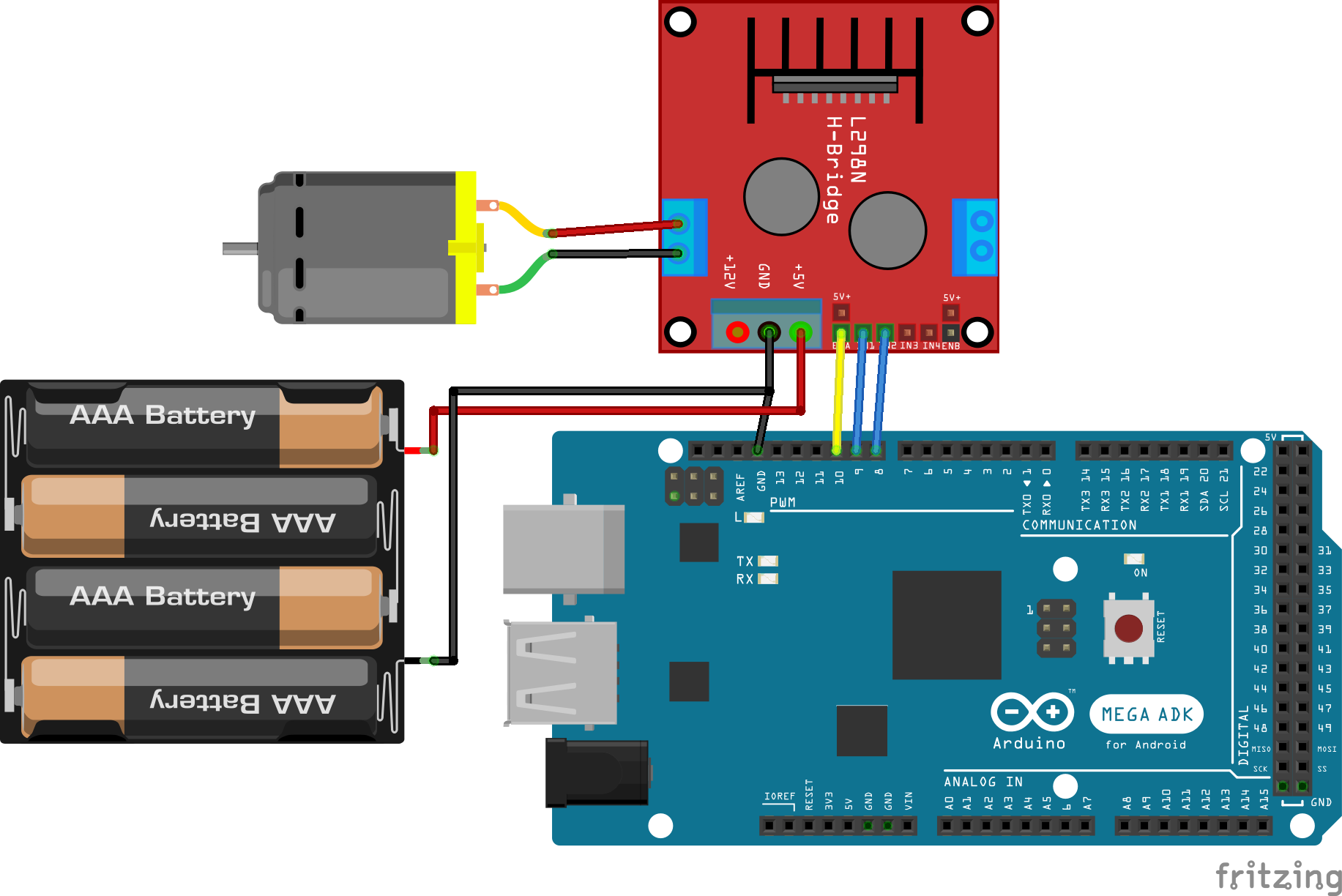

In a typical application, power connections are made on one side of the board and control connections are made on the other. Minimal wiring diagram for connecting a microcontroller to a DRV8833 dual motor driver carrier.

Since this board is a carrier for the DRV8833, we recommend careful reading of the DRV8833 datasheet. It can supply up to about 1.2 A per channel continuously and can tolerate peak currents up to 2 A per channel for a few seconds, making it an ideal driver for small motors that run on relatively low voltages. Texas Instruments’ DRV8833 is a dual H-bridge motor driver IC that can be used for bidirectional control of two brushed DC motors at 2.7 V to 10.8 V. Eventually make a number of changes together.I'm curious to see the outcome.īy the way, I suspect the sound is from the motor laminations changing shape at high frequency.DRV8833 dual motor driver carrier, bottom view with dimensions. Then reset that and change a different parameter, and so on. Change the delay between counts first, and report your results here. Now that I think about it, this is probably more important than the inertia and friction. Remember an inductor resists a change in current. I would also want to make the delay between counts higher so there is more time for current to flow in the motor's (inductive) windings. Also make the delay between counting up and counting back down much longer so you can actually see the effect before it counts down again. So I suggest you start the counter at say 125 or even higher. The motor well may run at the higher values of "i" but then the program immediately counts down again. On higher values I guess it's still not enough to overcome the inertia. You have very little power at low "i" so I'd be surprised if there is enough to overcome friction and inertia.

#L298N MOTOR DRIVER MAKING SOUND NOT MOVING FULL#

That would be a full rotation in about 800uS, say 1mS, or 1000 rotations in 1 second, or 60000rpm, from a standing start if the duty cycle was held constant. Most small DC motors are 2 pole, so you're expecting at least one 180degree rotation in 5x78uS or about in 400uS. At low values of i, a 180deg rotation has to occur in the time you apply the pulse for the motor to rotate, well not exactly but close enough. At low values of "i", say i=10, then the pulse is only 10/255*2ms wide or about 78uS. So in 10 ms you get 5 pulses of the same amplitude and smoothed by the cap. It seems to me that AnalogWrite generates a PWM signal of about 500hz or about 2ms wave period.

Besides that the whole thing is over in 5 seconds. I'm wondering if a 10 ms delay between steps is long enough for the motor to respond, especially with a cap across its terminals.

0 kommentar(er)

0 kommentar(er)